In the evolving field of product design, the drive for innovation has consistently propelled technological progress. From the precision of pre-industrial craftsmen to the groundbreaking introduction of assembly lines by Henry Ford, each major advance in product development has significantly reshaped industries. The introduction of digital design tools and computer-aided manufacturing in recent years has accelerated the pace of innovation, enabling designers to create more intricate and sophisticated products efficiently. Today, as we edge into a new technological era, generative AI emerges as a pivotal force poised to redefine traditional product design paradigms.

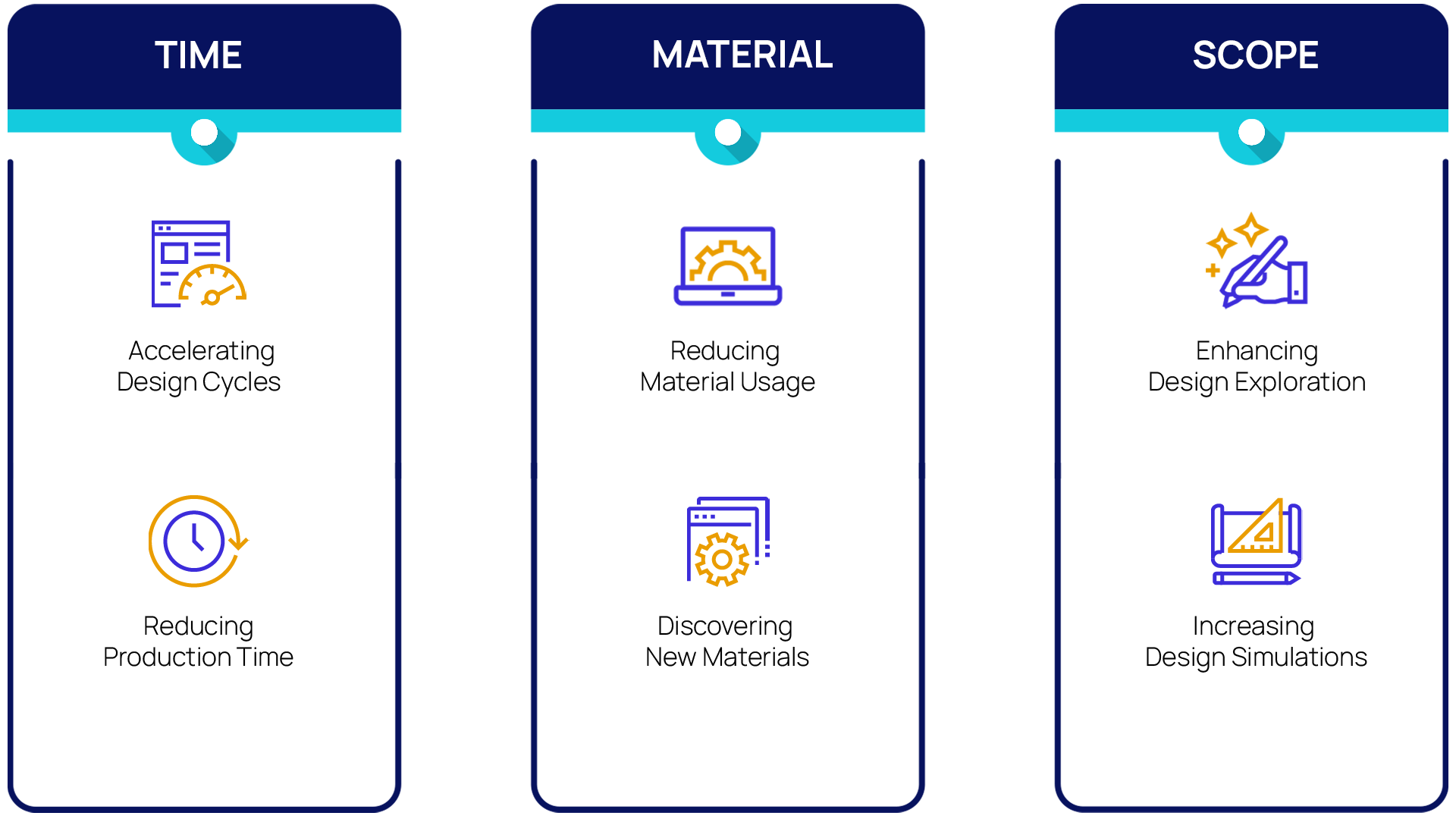

Generative AI harnesses sophisticated algorithms that generate optimized designs from predefined parameters, offering the potential to shorten design cycles, augment product functionality, and overhaul traditional manufacturing techniques. Leveraging generative AI in product development enhances product design and development across multiple dimensions:

- Reducing design and production time

- Reducing material usage and discovering new materials

- Expanding the design space and increasing design simulations

Accelerating Design Cycles

Generative AI in product design dramatically shortens traditional design cycles by quickly generating, evaluating, and refining prototypes. This rapid iteration not only speeds up the development process but also helps in meeting market demands faster.

Real-World Application: A leading global automaker has applied generative AI to redesign components such as the chassis frame and brake rotors for new models. The AI systems provide multiple iterations of component designs that optimize materials, durability, and weight distribution in a fraction of the time it would take human engineers.

Impact: This acceleration in the design phase significantly reduces the product’s time-to-market, allowing companies to stay competitive in fast-changing industries by rapidly adapting to modern technologies and consumer demands.

Reducing Material Use and Production Time

Generative AI optimizes production timelines and minimizes material usage by analyzing numerous design options that cater to performance needs. This method enhances manufacturing efficiency, cuts costs, and reduces environmental impact by ensuring that materials are used more judiciously without compromising product quality.

Real-World Application: A major European aerospace manufacturer uses generative AI to optimize the shapes and materials of aircraft parts. This approach has allowed the company to reduce the weight of components such as partition panels and mount brackets, which in turn decreases fuel consumption and CO2 emissions.

Impact: This streamlined approach not only refines the production process but also supports sustainability by significantly lowering the material wastage typical in traditional manufacturing methods.

Discovering New Materials

Generative AI’s capability to discover and optimize new materials is pivotal. It enables the creation of compounds with desired properties such as enhanced strength, reduced weight, or improved thermal resistance. This process involves the AI predicting material behaviors and properties, which can lead to revolutionary new materials that could transform entire industries.

Real-World Application: At a research institute in California, scientists are leveraging Gen AI to revolutionize the materials used in batteries. Generative AI predicts the properties of potential new battery materials, which can lead to batteries that charge faster, last longer, and perform efficiently under a variety of temperatures. Moreover, using AI combined with high-throughput automated laboratories, the institute can rapidly synthesize and test hundreds of new materials, dramatically accelerating the experimental process from years to days.

Impact: The development of new materials through generative AI not only fosters innovation in products but also enhances their sustainability and performance. By reducing the reliance on rare or environmentally damaging resources, these new materials offer improved performance and less ecological impact.

Increasing Design Simulations

Generative AI employs complex algorithms to generate multiple design alternatives from defined criteria, enabling rapid prototyping and iterative testing. This capability improves the ideation and refinement stages of product development and ensures the final product meets ambitious quality and functionality standards.

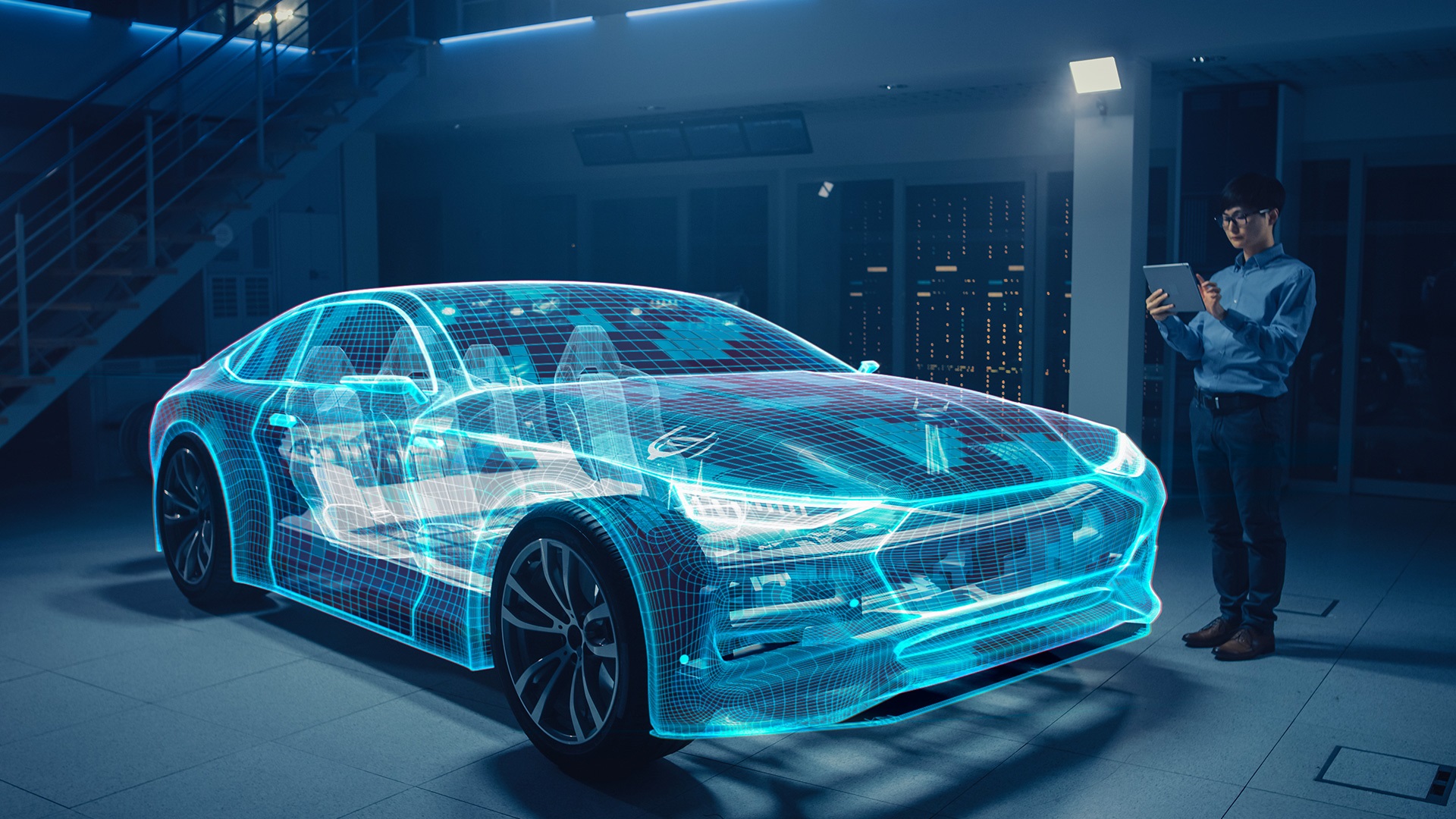

Real-World Application: In the automotive industry, a leading electric vehicle manufacturer uses generative AI to simulate different car body designs under various conditions to identify the optimal structures that improve aerodynamics and safety while reducing manufacturing costs.

Impact: Such extensive simulations help significantly reduce the number of physical prototypes needed, thereby saving on materials and speeding up the development cycle. The result is a quicker validation process and enhanced product quality finely tuned to meet specific performance criteria.

Enhancing Design Exploration

Generative AI automates the exploration of vast design spaces, which enables the discovery of innovative solutions that traditional methods may overlook. This technology explores all permutations of a design within the specified constraints to improve product performance and efficiency.

Real-World Application: A prominent sports apparel brand has deployed generative AI to design innovative footwear. AI analyzes millions of shapes and structures to optimize the midsoles for weight, performance, and material usage.

Impact: The ability to automate and expand design exploration helps companies drastically cut down on development time and introduce products that are at the forefront of technology and design.

Conclusion

Reflecting on the evolution from pre-industrial craftsmanship to today’s high-tech processes, it is evident that generative AI is not just a step but a significant leap forward in product development. This technology redefines design paradigms, much like the introduction of assembly lines did in Henry Ford’s era. From reducing development times in the automotive sector to optimizing material usage in aerospace manufacturing, generative AI transforms not only existing processes but also the entire way we conceive, design, and manufacture products.

Now is the time to explore the capabilities of generative AI in product development. Whether you are a designer or a business leader, integrating this technology into your operations can propel your products and processes forward. Engage with generative AI, collaborate with experts, and invest in the necessary tools and training to unlock its transformative potential. Embrace this technology to actively shape the future of design innovation.