In today’s rapidly evolving business landscape, supply chain management has become a complex orchestration of global operations, involving a multitude of stakeholders, data points, and logistical challenges.

To thrive in this environment, organizations are turning to advanced technologies, and at the forefront of this transformation stands generative AI. The use of generative AI within the supply chain is expected to result in CAGR growth of 45.3% during the forecast period from 2023 to 2032, according to a recent report.

In this era of heightened demand for efficiency, responsiveness, and data-driven decision-making, generative AI holds the promise of revolutionizing supply chain control towers, providing businesses with unprecedented insights, predictive capabilities, and agility. This article explores the exciting convergence of generative AI and supply chain control towers, offering a glimpse into how this synergy is poised to reshape the future of supply chain management.

Evolution of the Supply Chain Control Tower

While the concept of a supply chain control tower is not new, its capabilities and applications have evolved over time. Traditionally serving as a technological platform for businesses, control towers have offered stakeholders real-time visibility into key performance metrics.

With the advent of AI – especially generative AI – there is an opportunity to imbue these supply chain control towers with advanced problem-solving capabilities, enabling faster navigation of various challenges and the provision of more efficient solutions.

COVID-19: Reshaping the Supply Chain Landscape

The pandemic delivered a stark reminder of the vulnerabilities ingrained in global supply chains. With sudden lockdowns, fluctuating demands, and transport disruptions, the importance of robust risk modeling and scenario planning came to the fore. These unforeseen challenges underscored the significance of agile and responsive supply chain control towers in ensuring resilience and continuity.

Augmenting Supply Chain Control Tower with Generative AI

Supply chain control towers can continuously evolve using generative AI, which considers multiple scenarios and simulates results to make rapid and precise decisions. Generative AI can provide timely notifications and suggest flexible actions to minimize disruptions.

The integration of generative AI in supply chain control towers offers a plethora of benefits:

- Pattern Recognition: Identifying and proactively addressing supply chain anomalies to ensure smooth operations

- Optimal Pathways: Utilizing data to determine the most efficient transport routes and schedules

- Adaptive Sourcing: Highlighting alternative suppliers based on real-time market dynamics

- Demand Forecasting: Predicting shifts in market demand based on patterns and external factors

- Inventory Management: Optimizing stock levels, reducing carrying costs, and mitigating stockouts or overstock situations

- Supplier Risk Assessment: Evaluating suppliers for potential risks to ensure a stable supply chain

- Automated Troubleshooting: Identifying disruptions and autonomously devising solutions

- Sustainability Insights: Evaluating the environmental impact of supply routes and suggesting greener alternatives

- Enhanced Collaboration: Facilitating seamless communication between stakeholders for faster decision-making

- Scenario Simulation: Modeling various supply chain control tower scenarios to strategize solutions for potential challenges

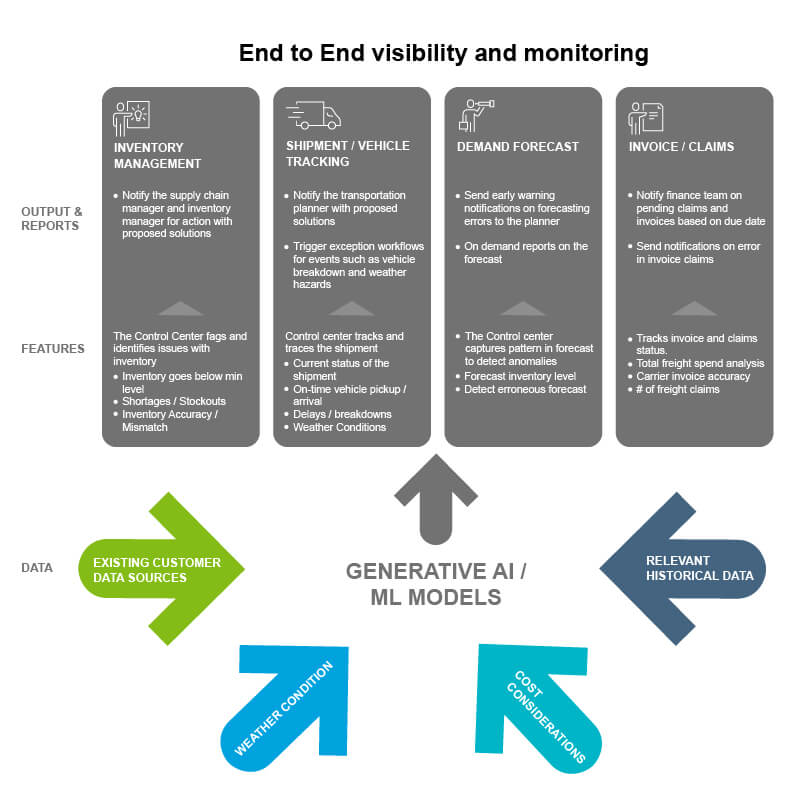

Representative Use Case Workflow

The flexible engineering capabilities – enabled by large language models – allow users to customize responses. With continuous data integration, the model evolves and adapts its datasets to specific scenarios. This reduces development time and can assist users in creating applications that meet their specific needs, representing a transformative potential for businesses.

Challenges of Leveraging Generative AI In Supply Chain Control Towers

Although generative AI has caused significant excitement and seems promising, one must remain mindful of the challenges associated with AI-related modeling:

- Data Dependency: Generative AI relies on high-quality data. In the context of gen AI in supply chains, acquiring reliable data, while considering user demand dynamics, production schedules, and logistics, can be challenging. For generative AI models to be effective, data gathering, cleansing, and integration are essential to trigger the right exceptions and alerts from a control tower perspective.

- Intensive Training: Training AI models demands substantial computational power and expertise. Managing trade-offs between model complexity and performance, selecting optimal model structures, and fine-tuning parameters can present significant challenges.

- Data Privacy: With regulations like GDPR in play, safeguarding sensitive data is of utmost importance. Organizations must ensure robust and foolproof measures to protect sensitive information.

Environment Social and Governance and Transparency across the Supply Chain

Environmental, Social, and Governance (ESG) factors have become a top priority for businesses worldwide. With stakeholders demanding greater transparency and responsibility, companies face increasing pressure to ensure their supply chains are ethical, sustainable, and compliant. The complexity arises when businesses must monitor various processes, right from sourcing raw materials to delivering the final product, to ensure that they meet ESG standards. This is where control towers – enhanced by generative AI – can play a pivotal role:

- Real-time Monitoring: Control towers provide a centralized platform to track various ESG metrics in real-time. Whether it is monitoring carbon emissions from transportation or ensuring ethical labor practices in manufacturing units, businesses can maintain vigilance and ensure compliance.

- Data-driven Insights: Generative AI can sift through vast amounts of data to identify potential ESG risks or areas for improvement. For example, if a supplier is flagged for environmental violations, AI can quickly alert decision-makers.

- Scenario Simulation: One of the standout capabilities of generative AI is simulating different scenarios. Companies can use this to model potential ESG challenges and develop preemptive strategies, staying ahead of potential pitfalls.

- Transparency and Trust: As consumers and stakeholders demand greater insight into supply chain practices, generative AI can assist in generating clear, understandable reports. This not only ensures transparency but also builds trust among stakeholders. Blockchain technology can be leveraged to ensure transparency of decisions across stakeholders.

In essence, by leveraging control towers integrated with generative AI, businesses can ensure that their supply chains are efficient and resilient while adhering to the highest ESG standards, contributing to a more sustainable and ethical future.

Conclusion

Generative AI holds the promise to transform the dynamics of supply chains. With increasing investments in AI, businesses should consider incorporating AI into their supply chain control towers, especially due to their compatibility with technologies like digital twins and vision tech. By ensuring adequate training and seamless integration, these AI-powered towers can drive enhanced efficiency and responsiveness throughout the supply chain.