Hexaware Acquires SMC Squared, a Leader in Building Global Capability Centers-Rolls Out GCC 2.0 Service Line. Learn More

This website uses cookies. By continuing to browse the site, you are agreeing to our use of cookies

How Digital Disruption Impacts Manufacturing Industry

Manufacturing

September 27, 2018

Digital transformation is the present Industrial Revolution. The rise of informed customers and innovative technologies have made the manufacturing industry an example of how effective modern operational strategies can reshape the overall operations of an organization. The amalgamation of production techniques with the latest technological developments have the potential to make manufacturing autonomous, cheaper and more efficient. Robotics, the Internet of Things (IoT), data analytics and 3D printing are just few of the digital solutions disrupting the space. This makes many organizations turn to IT consultancy for guidance.

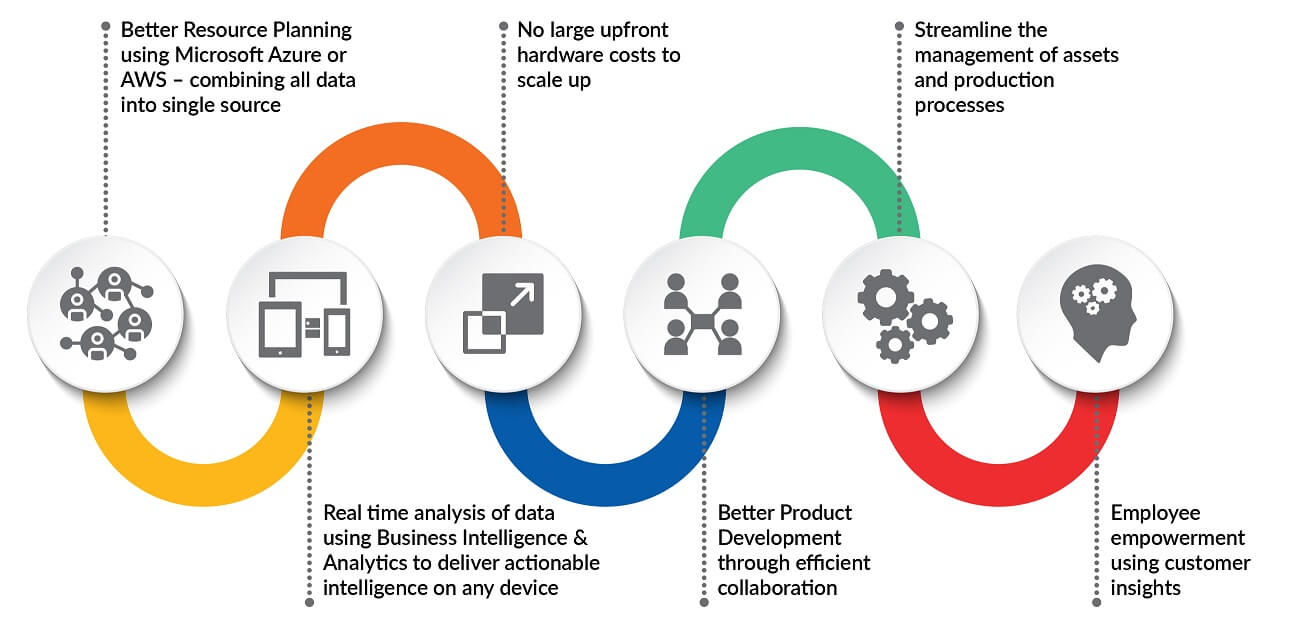

The below given infographic gives an idea of what digitization looks like in manufacturing space.

Smart Manufacturing: The Fourth Industrial Revolution

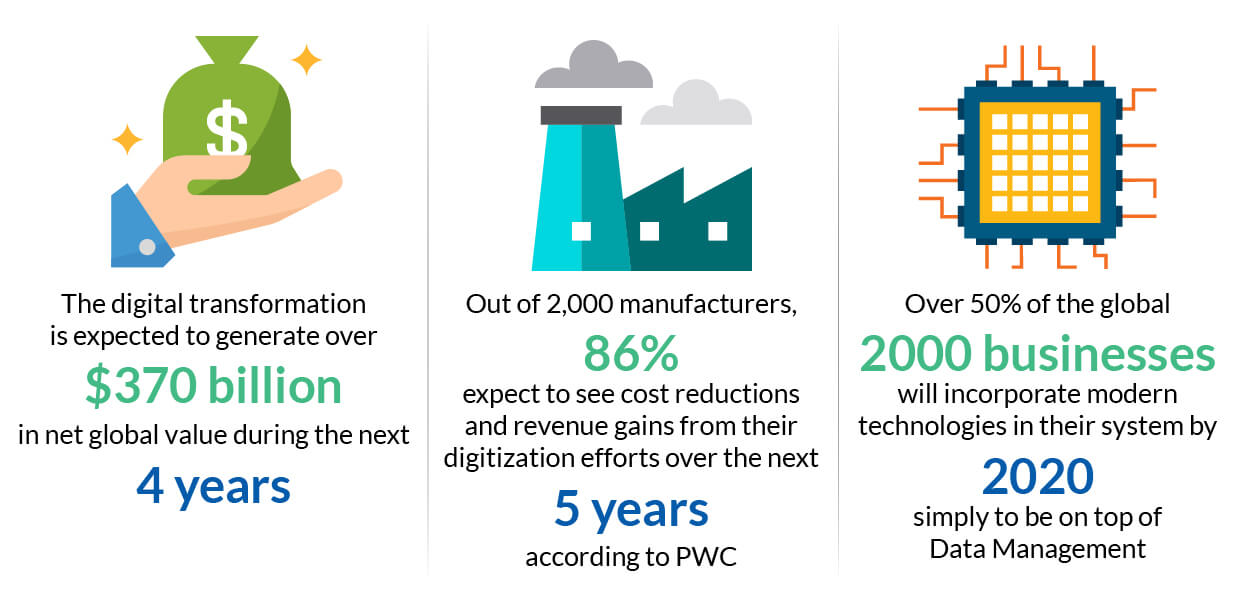

There is an incessant flow of new services that continue to disrupt the industry. Hexaware encourages companies to take advantage of these disruptions to the market. Given below are some global statistics that prove how digitalization has taken the world by storm and how most companies are embracing it.

This fourth industrial revolution is moving manufacturers from mass production to customized production through a digital supply network. Companies are keen on creating digitally enhanced product lines and services to improve operational efficiencies. While many have embraced digitalization by investing in newest technologies like IoT, AI, machine learning, advanced robotics, 3D printing, most fail to understand the ground reality of creating a digitized ecosystem for businesses to thrive.

We believe that digitization empowers manufacturers, suppliers, collaborators, and customers to become one seamlessly integrated transparent ecosystem. This doesn’t happen overnight though. Manufacturers need to re-design their processes, operations, and IT systems to be more agile and competitive. It requires a change in overall mindset, adoption of latest technologies like cloud infrastructure, alterations in processes that support these technologies etc., to enable greater productivity, efficiency and lower costs.

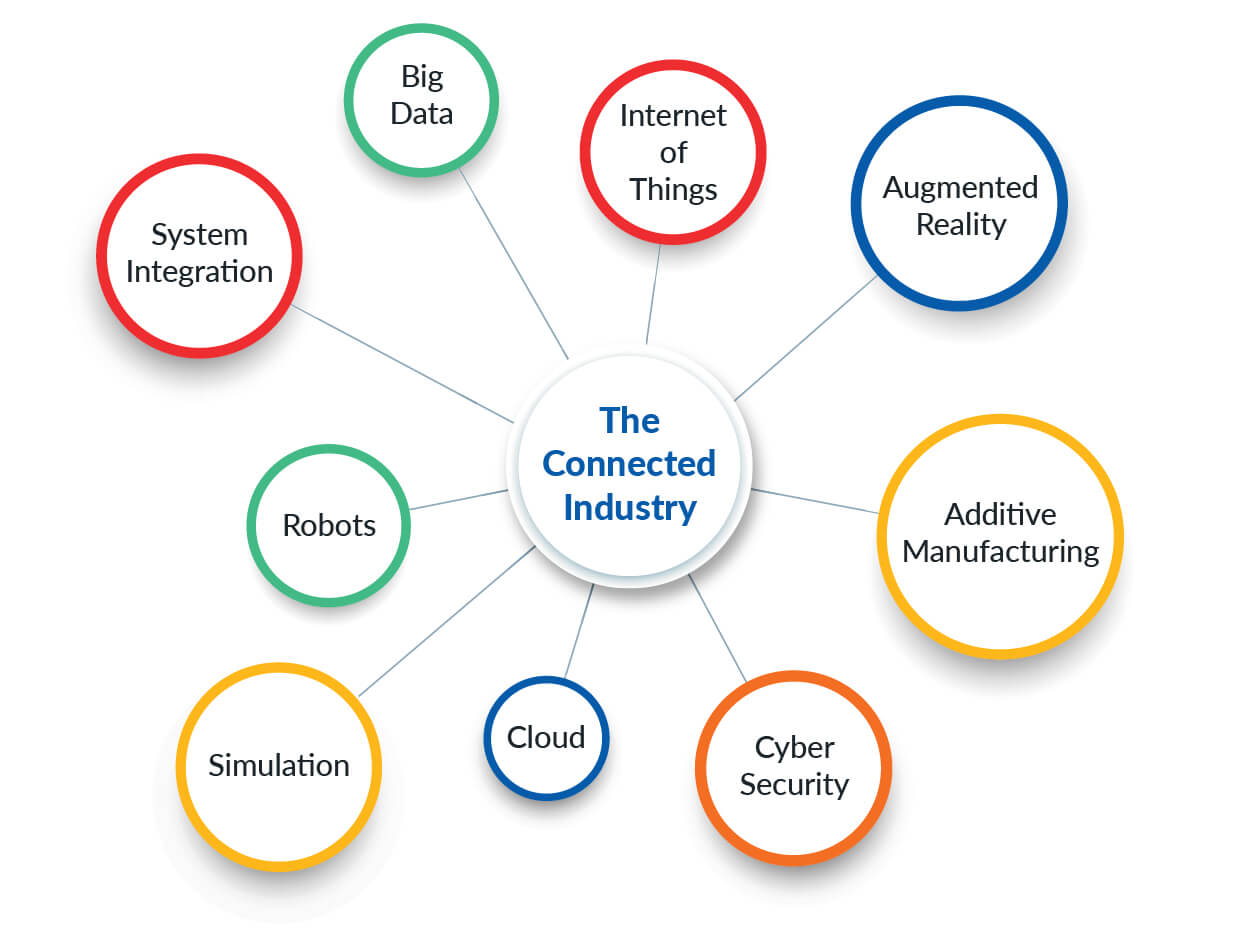

Human-Machine Collaboration for a Connected Industry

Automating processes in a factory offers efficient processes, self-regulating optimization and configuration. Hexaware strongly promotes automation – the collaboration between humans and machines, to further the growth of manufacturing industry. Today, robots in industries are on the edge of transforming manufacturing with competences that imitate human traits like memory and adroitness, which makes them more operative in industries like manufacturing.

Hexaware focuses on three disruptive technologies – IoT, Big Data and augmented reality to transform manufacturing business. With augmented reality, we help with designing better products, diagnosing existing problems, and enabling better productivity. We are also at the forefront of Big Data technology to develop industry-specific use case repositories that will benefit from this new technology and help companies make the right decision. Our expertise and research in IoT help us develop seamless business applications and technology solutions, thereby helping manufacturers leverage these technologies to their best potential.

The Future of Manufacturing: The Connected World

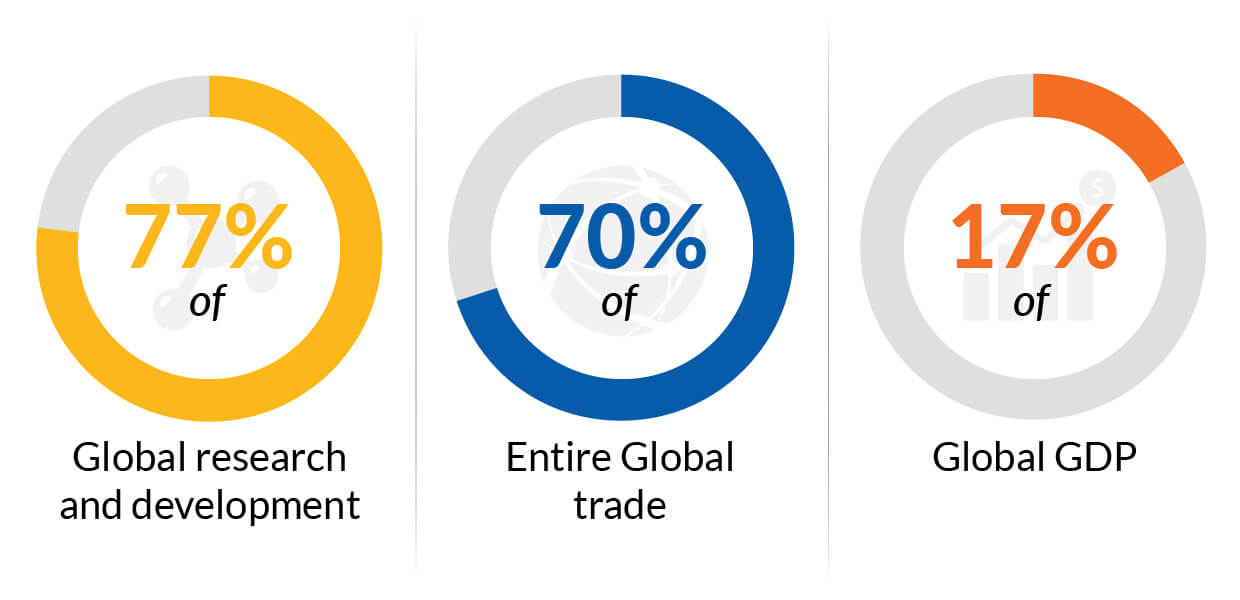

Manufacturing is at the core of a robust economy. Some of its contributions are:

Hence, automating everything and cloudifying everything holds a strong importance, not only in the growth of manufacturing business, but the nation’s economy at large.

Imagine how seamless manufacturer’s business operations will be if the interconnectivity is flawless. Say for example:

- Operations teams can access real-time information on the process, inventory, and order status by automating and integrating business processes.

- R&D teams and product design teams can communicate in real-time with on-floor employees to achieve a high level of quality control.

- Product development team can embed sensors, actuators and digital identification tags within production lines, and products can be used in the field by customers to provide greater insight into methods for improving the quality of products.

- Operations managers can automate data flow in real time across a business ecosystem using cloud-based platforms that provide secure access and data exchange.

The idea of the interconnected factory is on its way, where all the equipment can be online, and in some way can also be intellectual and proficient of making its own decisions. The connected factory is the future in store for us. Leveraging IoT, machine learning, Big Data and augmented reality, the connected factory can lead to the removal of data silos, machine-to-machine communication, optimization of value chain and operations, and proactive machine maintenance. We are still a long way from being in a world where the interconnected factory is a normal in manufacturing, but by embracing human-machine collaboration, we intend to get there in a few years.

Hexaware’s Manufacturing & Consumer Practice offers deep domain knowledge, skills, and experienced practitioners who have worked with leading organizations on complex cross-functional solutions.

Related Blogs

Transforming Manufacturing Sales: From Complexity to Simplicity with CPQ for Manufacturing

- Manufacturing

Gen AI: The Formidable Force in Optimizing Warranty Provisioning

- Manufacturing

- Generative AI

The New Era of Design: Embracing Generative AI in Product Development

- Manufacturing

- Generative AI

Generative AI for Architecture, Engineering and Construction Industry

- Manufacturing

- Generative AI

Embracing Generative AI in Manufacturing: Insights from Hexaware Technologies

- Manufacturing

- Generative AI

Generative AI-Enabled Supply Chain Control Tower

- Manufacturing

- Generative AI

Ready to Pursue Opportunity?

Every outcome starts with a conversation