Introduction

Supply chain disruptions continue to dominate the business landscape, with 88% of supply chain leaders reporting that risk and resilience remain top priorities in 2024, according to McKinsey’s Global Supply Chain Leader Survey. From geopolitical tensions to climate-related risks and economic instability, the challenges facing global supply chains are more complex than ever.

To navigate these uncertainties, businesses are turning to innovative solutions like the Supply Chain Control Tower—a centralized platform that provides real-time visibility, predictive analytics, and actionable insights. By leveraging advanced technologies such as AI in supply chain management, companies can enhance Supply Chain Resilience, achieve Supply Chain Optimization, and drive cost reduction in supply chain operations.

In this blog, we’ll explore how Supply Chain Control Towers are transforming the way businesses manage their supply chains, enabling them to stay competitive in an increasingly volatile world.

What is a Supply Chain Control Tower?

A supply chain control tower is a centralized platform that provides businesses with real-time data, analytics, and actionable insights across their entire supply chain. Unlike traditional supply chain systems, which often operate in silos, the control tower integrates multiple data sources, creating a holistic view of operations. This enables organizations to:

- Predict and mitigate disruptions proactively.

- Drive supply chain optimization through data-driven decisions.

- Enhance agility in adapting to market changes.

- Foster Supply Chain Automation to reduce manual errors and inefficiencies.

The evolution of the supply chain control tower has been remarkable. What started as basic monitoring systems has transformed into sophisticated, AI-powered platforms capable of delivering end-to-end visibility and self-learning capabilities. Here’s a quick look at this evolution:

|

Stage |

Past |

Present |

Future |

|

Focus |

Manual, reactive systems for monitoring |

Real-time data integration and AI-driven decision-making |

Autonomous supply chains using digital twins, AI, and 5G for seamless, continuous optimization |

|

Outcome |

Limited visibility and slow decision-making |

Proactive control of operations through predictive analytics |

Self-learning systems capable of real-time adaptability and advanced supply chain automation |

Why Businesses Need a Control Tower

Global supply chains are more vulnerable than ever. A supply chain control tower empowers businesses by providing:

Predictive Insights

With the power of AI in supply chain management, control towers can forecast potential disruptions, such as supplier delays or demand surges, and recommend preventive actions. This predictive capability ensures minimal downtime and uninterrupted operations.

Enhanced Agility

The SCCT leverages real-time data to help businesses respond quickly to demand fluctuations, supply shortages, or bottlenecks. This agility is key to maintaining supply chain resilience in volatile markets.

Expanded Visibility

A centralized control tower provides a comprehensive, real-time view of the entire supply chain—from production to delivery. This transparency allows businesses to identify inefficiencies and bottlenecks before they escalate.

Cost Reduction in Supply Chain

By optimizing logistics, inventory management, and procurement, businesses can significantly reduce operational costs. For example, AI-driven route optimization can lower transportation costs, while dynamic inventory planning minimizes stockouts and excess inventory.

Improved Customer Satisfaction

Reliable, on-time deliveries and proactive issue resolution lead to better customer experiences. This not only enhances brand loyalty but also provides a competitive edge in saturated markets.

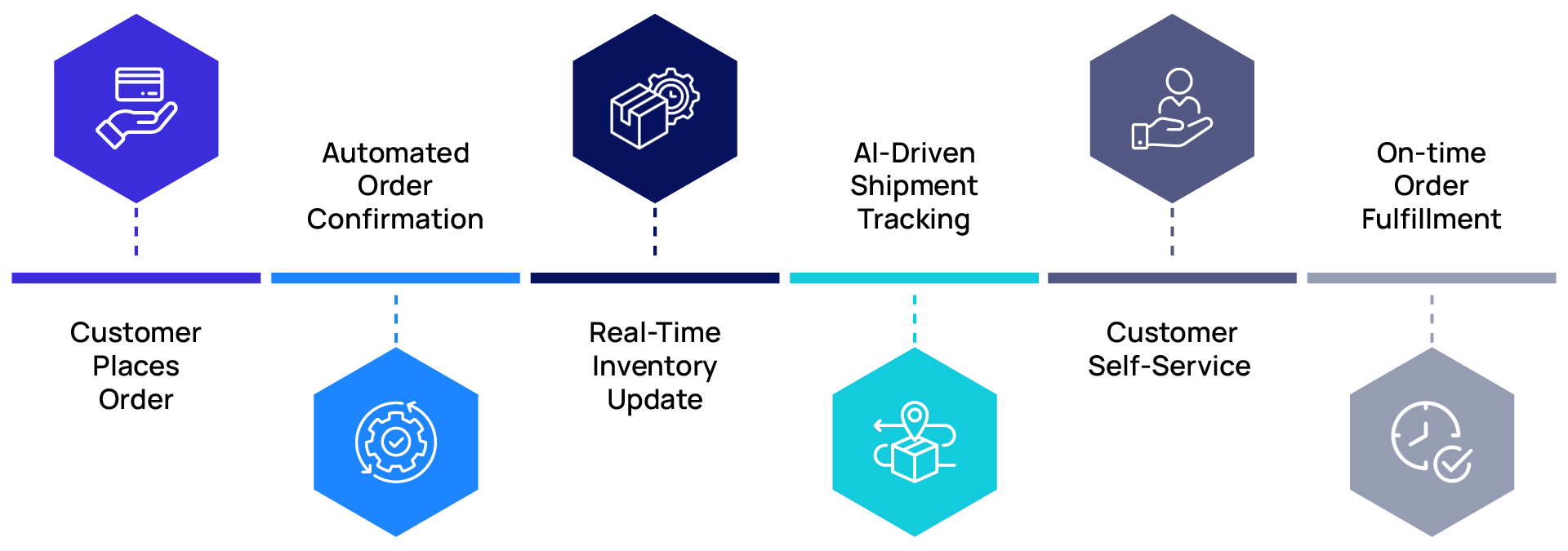

Before and After: Transforming Supply Chain Interactions with a Control Tower

The implementation of a supply chain control tower marks a dramatic shift in how businesses manage their supply chain operations. Before adopting a control tower, supply chain processes were often manual, fragmented, and reactive. This led to inefficiencies such as delayed order fulfillment, poor visibility, and a lack of proactive decision-making.

The infographic below illustrates the challenges of pre-control tower workflows, where users relied on manual processes like spreadsheets, emails, and phone calls to track shipments, manage inventory, and resolve disruptions. These outdated methods often resulted in delayed responses to issues, increased costs, and dissatisfied customers.

In contrast, the second infographic demonstrates the transformative impact of a control tower. With supply chain automation and real-time data integration, businesses can achieve seamless workflows, proactive issue resolution, and on-time order fulfillment. Automated alerts, AI-driven insights, and centralized dashboards empower users to make faster, data-driven decisions, improving both efficiency and customer satisfaction.

These visuals highlight the tangible benefits of implementing a supply chain control tower, showcasing how it enables businesses to transition from reactive, manual processes to proactive, automated operations.

How Control Tower Works

Supply Chain Control Towers (SCCTs) are becoming increasingly important across industries like manufacturing, automotive, retail & e-commerce, and consumer goods. SCCTs aggregate data from various sources, including ERP systems, IoT sensors, and cloud platforms. This data is then analyzed to identify inefficiencies and recommend corrective actions. Let’s explore some of the functional areas to better understand the impact of a supply chain control tower.

Demand Planning and Forecasting

|

Stage |

Before SCCT |

After SCCT |

|

Data Collection |

Demand planners manually pull historical sales data from multiple systems (ERP, WMS, spreadsheets) |

AI-driven control tower automatically integrates sales, market trends, and external factors (weather, economic indicators) in real-time |

|

Forecasting |

Often based on historical trends with little predictive analytics, leading to stock imbalances |

Machine learning algorithms generate dynamic, demand-sensing forecasts, improving accuracy |

|

Decision Making |

Planners react to sudden demand shifts manually, often leading to over/understocking |

Automated alerts recommend inventory adjustments before demand spikes or drops occur

|

Procurement and Supply Management

|

Stage |

Before SCCT |

After SCCT |

|

Supplier Performance |

No centralized tracking, performance metrics tracked manually |

Automated scorecards evaluate suppliers on lead time, quality, and reliability, triggering corrective actions when needed |

|

Disruptions and Risk Management |

Disruptions (e.g., raw material delays) discovered late, forcing last-minute adjustments |

AI-based risk prediction alerts buyers to potential supplier delays and suggests alternate sources |

Logistics and Transportation

|

Stage |

Before SCCT |

After SCCT |

|

Shipment Tracking |

Users rely on carrier portals, manual tracking, or customer service inquiries |

Centralized real-time visibility of all shipments via IoT and GPS integration |

|

Route Optimization |

Routes planned manually without considering real-time traffic, weather, or carrier constraints |

AI-driven optimization recommends the best routes based on live conditions, reducing delivery times and cost |

|

Exception Management |

Issues (e.g., shipment delays, damages) are managed reactively after customer complaints |

Proactive alerts for potential disruptions with automated recommendations for alternative logistics options |

Inventory Management

|

Stage |

Before SCCT |

After SCCT |

|

Stock level monitoring |

Warehouse teams manually check stock levels, leading to delays in replenishment |

AI-powered dashboards provide real-time inventory insights and recommend re-order quantities |

|

Replenishment Planning |

Orders are placed based on static reorder points, often resulting in stockouts or overstock |

Dynamic, data-driven replenishment based on demand fluctuations, reducing excess stock and stockouts |

|

Warehouse |

Warehouse managers coordinate via emails/calls, causing inefficiencies |

Automated task assignments improve order picking, packing, and replenishment |

Value Proposition: Unlocking the True Potential of Supply Chain Control Towers

The true value of a supply chain control tower lies in its ability to provide organizations with a centralized, real-time, and holistic view of their entire supply chain. By integrating data from multiple sources and leveraging advanced technologies like AI in supply chain management, control towers empower businesses to achieve significant improvements in efficiency, resilience, and scalability.

The figure below highlights the potential savings and benefits organizations can anticipate with a fully operational control tower:

|

Operational efficiency |

Risk Mitigation |

Labor Efficiency |

Scalability and Flexibility |

|

10-20% |

20-40% |

10-15% |

20-30% |

|

Reduced SCM costs (warehousing, inventory transportation…) |

Reduced supply chain disruptions potentially saving millions of dollars in lost revenue, penalties, and reputational damage

|

Automation and error reduction can lead to improvement in labor productivity and reduced costs associated with error

|

Businesses that experience rapid growth, or global expansion can benefit from savings in operational costs

|

These benefits demonstrate how a supply chain control tower not only enhances supply chain resilience but also drives cost reduction in supply chain operations. By automating processes, improving visibility, and enabling data-driven decision-making, businesses can unlock new levels of efficiency and agility.

What the Future Holds

The future supply chain control tower will be proactive, self-learning, and fully interconnected. It will evolve from a reactive monitoring tool into an AI-powered, autonomous command center that can predict disruptions, optimize routes, and manage supply chains in real-time. Key advancements we anticipate include:

- Autonomous Decision-Making: AI-powered systems will dynamically reroute shipments, optimize sourcing, and resolve bottlenecks without human intervention.

- Digital Twins: Advanced simulations will allow organizations to test different scenarios and improve supply chain resilience.

- Hyperautomation & IoT Integration: Sensors and robotics will streamline processes, delivering faster insights and actions.

- Sustainability and ESG Compliance: Control towers will help monitor carbon footprints, ethical sourcing, and waste reduction efforts.

- Edge Computing: Faster, real-time decisions by processing data closer to the source.

Conclusion

The Supply Chain Control Tower is no longer a luxury but a necessity for businesses striving to achieve operational excellence and resilience. Exploring and implementing a supply chain control tower involves careful planning and strategic decision-making. By following a structured approach, starting with assessing current maturity, defining objectives, selecting the right technology, and scaling the solution, organizations can successfully implement a control tower that enhances visibility, agility, and decision-making across their entire supply chain. Investing in a robust SCCT is the key to staying competitive in today’s dynamic marketplace.

If you’re ready to transform your supply chain, consider partnering with Hexaware for supply chain consulting services. We can help guide you toward the right strategy and tools to unlock significant cost reduction in supply chain operations and future-proof your business.