Generative AI has become a definitive business imperative for manufacturing industries to enhance operational efficiency, drive innovation, and boost agility, resilience, and competitive advantage. It enables connected factories and streamlines operations from the supply chain to production, sales, and after-sales, thus elevating the customer experience.

With advancements in automation, Industry 4.0, and artificial intelligence, OEMs must continuously evolve their operations to optimize production processes and deliver competitive products. Today’s customers, faced with more choices than ever, expect a personalized experience delivered with speed and agility across their preferred channels, from marketing to after-sales.

Generative AI transforms customer service by enabling automated and real-time after-sales support, such as ordering parts and sending field assistance. It also predicts parts failures through data analysis and alerts the relevant people. Basically, gen AI can completely modernize the warranty process.

This blog focuses on how Gen AI helps manufacturers optimize the warranty provisioning landscape for efficient operations, happy customers, and sustainable business growth.

Warranty Provisioning: Inherent Challenges

Warranty claims processing is technology and business-system agnostic. Any pre-existing contract and warranty administration system can analyze and process warranty claims effectively.

However, warranty provisioning is a challenge for many manufacturers, and OEMs often cannot forecast or anticipate repair costs, warranty claims processing efforts, etc. Hence, deep learning and cognitive technology are essential for reading and analyzing warranty provisions based on history and service efforts.

The lack of accurate information is one of the biggest challenges in figuring out the real cost of product recalls and warranty claims. It is difficult to track recalls and claims, and estimating the potential financial exposure is challenging. Manufacturers and suppliers end up using broad cost-sharing agreements that are not based on detailed claims analysis.

Automotive and discrete manufacturers servicing low-value to high-end consumer durable products face the highest impact.

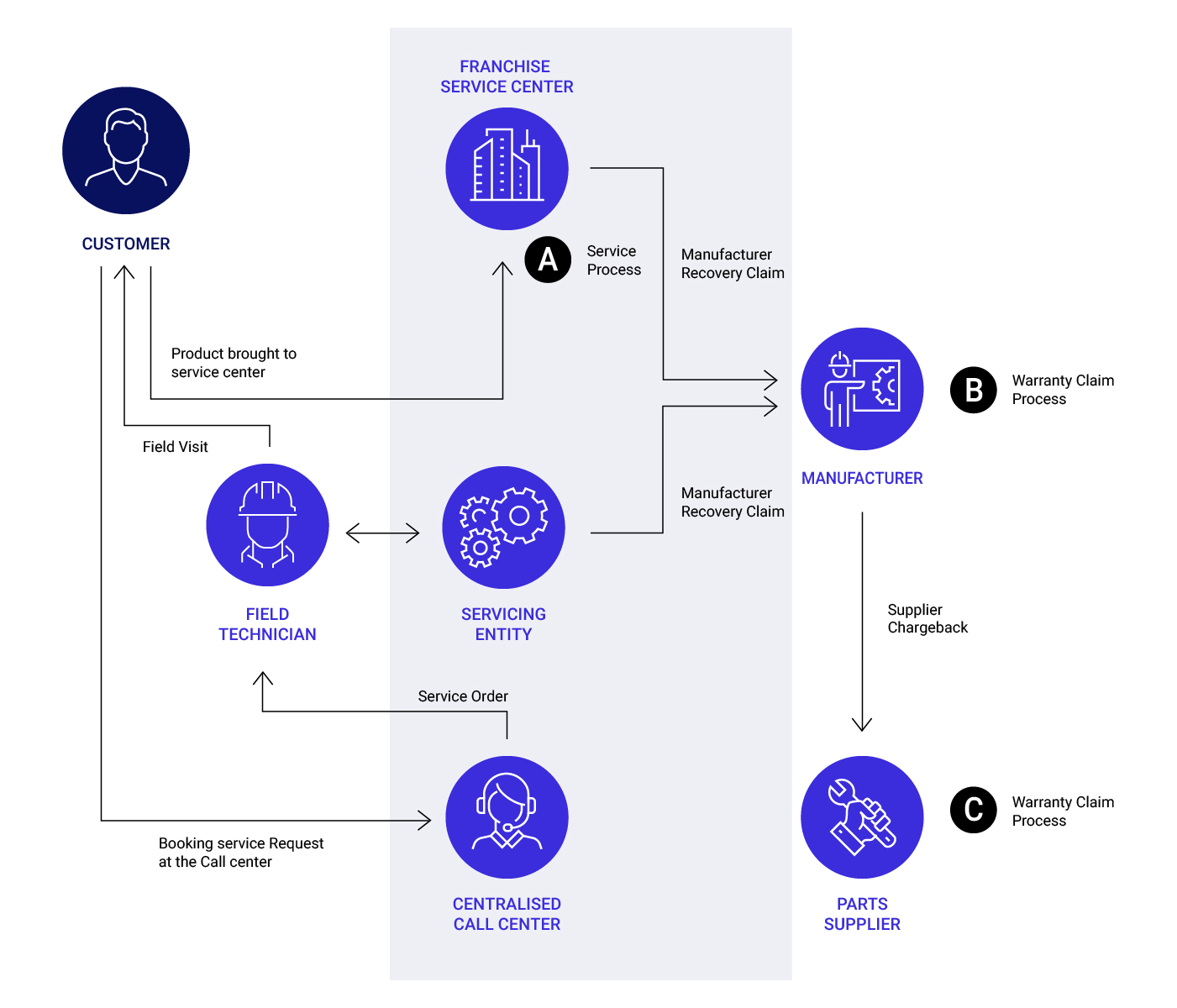

The Warranty Claim Process — An Explainer

In the warranty claim process, defective parts under warranty are replaced. Typically, the customer is not charged, but sometimes labor costs may be charged depending on the terms and conditions of the warranty. Similarly, if the warranty does not cover the defective parts, they are replaced and charged to the customer.

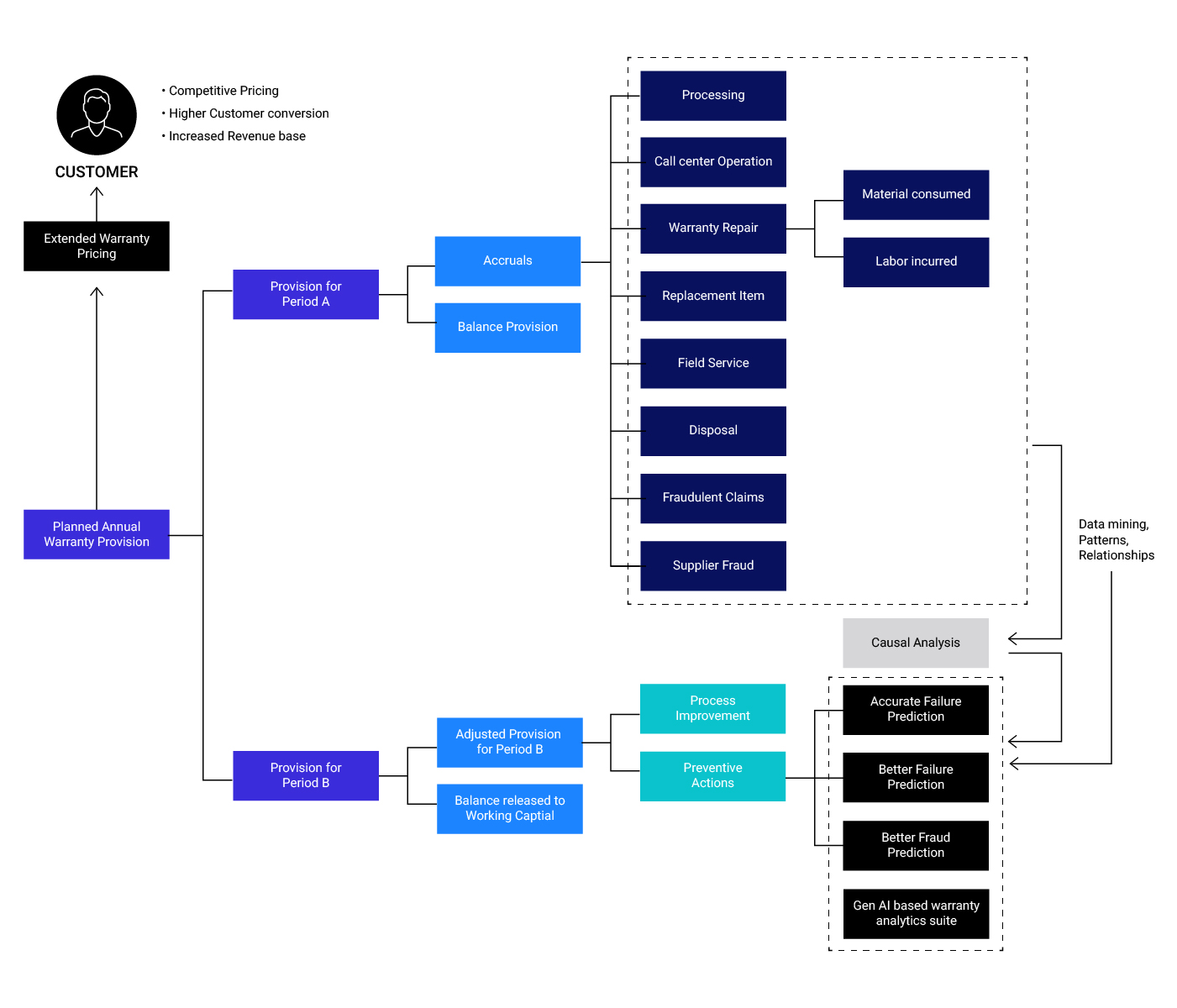

If the claim is attributable to the manufacturer, the claim charge remains. If the part suppliers are responsible, they receive a supplier recovery charge. Analytics and predictive models combined with generative AI patterns on product services, spare part consumption, financial data, accounting, and presentation of cost recoveries from suppliers and insurance policies help OEMs optimize warranty provisioning, the next horizon in warranty management forecasting.

Optimizing the Warranty Provisions with Gen AI

A comprehensive warranty analytics suite based can be developed on the general pattern of empirical warranty claims data. This suite will include an Aggregate Warranty Cost (AWC) forecasting model leveraging generative AI based on product sales, failure processes, claims charges, and supplier chargebacks. This model can be used to plan warranty provisioning with greater accuracy.

The Gen AI-based warranty analytics suite offers strategies on how manufacturers should predict and dynamically plan warranty provisions over the warranty lifecycle.

The Benefits of Leveraging Gen AI

Here are a few anticipated benefits of integrating generative AI in the warranty provisioning process:

- Reduction in manual effort of provisioning and analysis by more than 50%

- Increase in accuracy of warranty provisioning by 15-20%

- Increase in the adoption rate of extended warranty agreements by 20-30%

- Reduction in warranty costs by 15-20%

By setting reserved funds or resources to address potential warranty defects, manufacturers establish their dedication to delivering high-quality products, thus ensuring customer satisfaction. They can effectively utilize the warranty reserves with proper financial forecasting, risk mitigation, and warranty agreements to uphold guarantees and build persisting customer relationships.

To learn more about how you can drive winning outcomes by leveraging Gen AI, automation, and data analytics for your manufacturing value chain, check out our domain-specific IT solutions here.